Solomon Boakye-Yiadom1 and Nabil Bassim2

12Department of Mechanical Engineering, University of Manitoba, Winnipeg, MB, Canada, R3T 5V6 Materials exposed to high strain rates during impact may exhibit large deformations localized in narrow bands known as adiabatic shear bands (ASBs) [1-3]. ASBs are manifestations of damage because they are susceptible to crack nucleation and propagation due to their high internal stresses [1, 2]. The mechanisms of formation of adiabatic shear bands can be grouped into two main parts: thermomechanical mechanisms and microstructural mechanisms. The prevailing theory for the thermomechanical mechanisms of formation of adiabatic shear bands is that they form in narrow bands because of two competing mechanisms occurring sequentially: strain hardening followed by thermal softening from the retained heat because of conversion of plastic work into heat [2, 4]. On the other hand, the microstructural models assume that there is a significant change that occurs to the initial microstructure of the material during the passage of the stress waves when the material is deformed at high strain rates and large strain [2, 3].

Currently, a systematic study is performed on the nature of the microstructure of adiabatic shear bands in hardened steel to determine the mechanisms that result in the evolution of adiabatic shear bands during impact. It has been found that complex mechanisms including the emergence of dislocations, carbide dissolution, grain elongation, subgrain refinement and dynamic recrystallization, occur simultaneously which result in the non-equilibrium structure of the shear bands. It is also reported that all these mechanisms start up with the emergence of dislocation structures and the occurrence of all the other mechanisms are means of accommodating the excessive strains in the shear bands due to the passage of the stress waves through the specimen during impact.

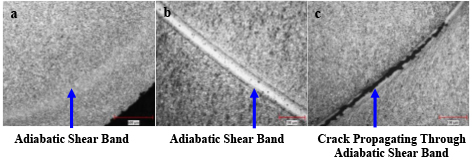

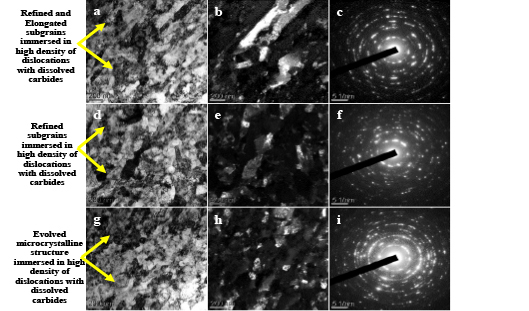

Figure 1 shows the optical micrographs of adiabatic shear bands in the impacted 425°C-1hr tempered steel specimens showing the evolution of the shear bands as impact momentum increases. The shear bands appear more distinctive and clear with the increase in impact momentum. Figure 2 shows transmission electron micrographs from regions within the shear bands which are induced in the steel specimens after impact. The most distinctive characteristic of the shear band structure was the morphology of the evolved grains and subgrains within the shear bands. The evolved grains within the shear bands did not have any resemblance to the initial structure of the steel specimens prior to impact. The dark contrast and the mottled appearance of the grains are as a result of the presence of high density of dislocations within the refined grains and evolved subgrains. The ring patterns on the SADP demonstrate the presence of fine grains within the shear bands. The ring pattern confirms grain refinement that occurs within the shear band structure which results in the evolution of microcrystalline structure immersed in high density of dislocations. The results confirm the essential role of dislocations which lead to the evolution of the shear bands.

[1] Yongbo Xu, Jinghua Zhang, Yilong Bai, And Marc Andre´ Meyers, Shear Localization in Dynamic Deformation: Microstructural Evolution, Metallurgical And Materials Transactions A 39 (2008) 811-841

[2] Nabil Bassim, Mesoscale manifestations of damage in metallic materials, 13th International Conference on Mesomechanics (2011) 1-3

[3] Solomon Boakye-Yiadom (Corresponding Author), Nabil Bassim, “A Microstructural Model For The Evolution Of Adiabatic Shear Bands In Hardened Alloy Steel”, E-TP-13-518-A , (2013) Metallurgical and Materials Transaction (Submitted for Publication)

[4] L. E. Murr, E. A. Trillo, S. Pappu, C. Kennedy, Adiabatic Shear Bands And Examples Of Their Role In Severe Plastic Deformation, Journal Of Materials Science 37 (2002) 3337 – 3360